Athermalized technology was developed

as part of a project:

Application of 3D Printing Technology to Build a Prototype 2D Camera Equipped with a Model for Temperature Drift Compensation

COMPETITION: Proof of Concept, Priority 2 of the EUROPEAN FUNDS FOR A MODERN ECONOMY 2021–2027 (FENG), Foundation for Polish Science

CALL FOR APPLICATIONS: 1/2023

APPLICATION NUMBER: FENG.02.07-IP.05-0258/23

TITLE: Application of 3D Printing Technology to Build a Prototype 2D Camera Equipped with a Model for Temperature Drift Compensation

PRINCIPAL INVESTIGATOR: Marcin Adamczyk

TEAM: Anna Pakuła, Robert Sitnik, Wojciech Załuski, Jakub Dziedzic, Małgorzata Olewińska

PROJECT DURATION: October 1, 2024 – September 30, 2025

FUNDS AWARDED FOR THE PROJECT: 601 650 PLN

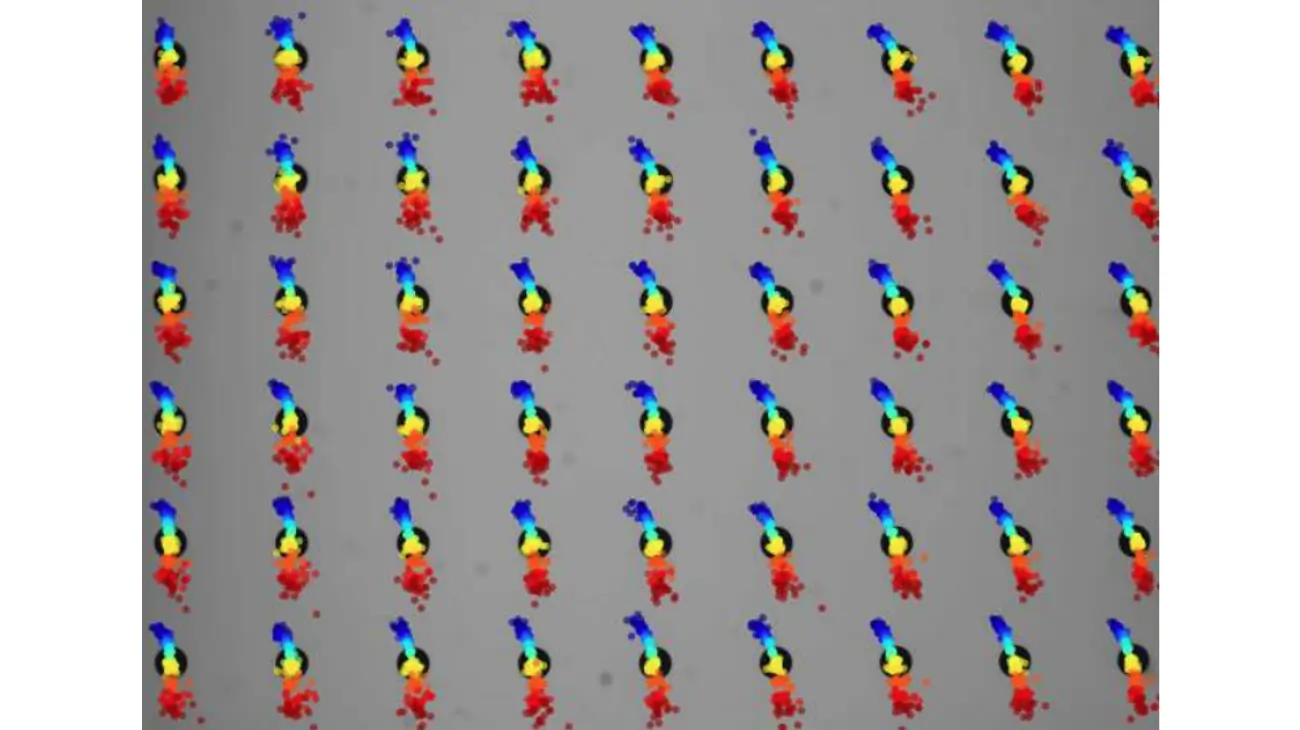

Temperature-induced image drift is observed in commonly used cameras with CCD and CMOS sensors because their optomechanical design is not optimized to reduce this phenomenon. In every metrological application where the camera is used as a sensor for recording measurement images, image deformation caused by camera temperature changes significantly deteriorates the final properties of the application. Depending on the measurement scene, camera temperature changes can result in image position shifts of up to several pixels.

For many vision sensor-based measurement applications, image shifts or deformations of even 1 pixel can translate into errors observed in the measurement scene reaching up to several dozen centimeters or more. A very important issue is the fact that temperature-induced image drift is, on one hand, a widespread phenomenon, and on the other hand: a phenomenon that is little known and often overlooked in metrological analysis. Research shows that temperature-induced image drift is inherently random in nature. This lack of repeatability is the reason why software methods for reducing temperature drift cannot properly compensate for the described phenomenon.

For many vision sensor-based measurement applications, image shifts or deformations of even 1 pixel can translate into errors observed in the measurement scene reaching up to several dozen centimeters or more. A very important issue is the fact that temperature-induced image drift is, on one hand, a widespread phenomenon, and on the other hand: a phenomenon that is little known and often overlooked in metrological analysis. Research shows that temperature-induced image drift is inherently random in nature. This lack of repeatability is the reason why software methods for reducing temperature drift cannot properly compensate for the described phenomenon.

The solution to these problems is Athermalized technology. It involves modifying the optomechanical construction of the camera by implementing a special compliant sensor suspension. Research indicates that the implementation of Athermalized technology eliminates the random nature of temperature-induced image drift, which in turn enables the implementation of a software compensation model. The end result is a reduction of temperature-induced image drift by over 80% and a significant improvement in the quality of recorded measurement images.

Latest News

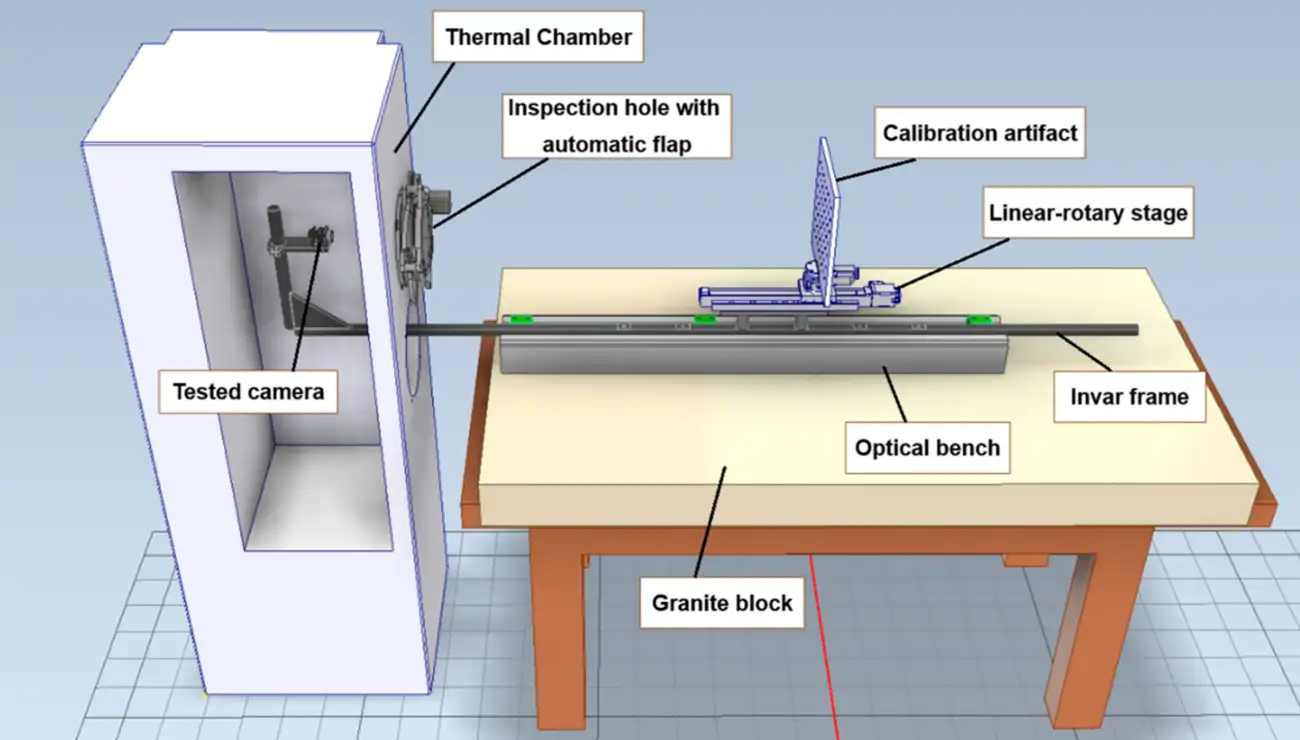

How to Properly Measure Thermal Image Drift in 2D Cameras

The Importance of Accurate Thermal Drift Measurements In precision imaging applications, even minor temperature variations can cause significant distortions in captured images. Thi

Athermalized Recognized by WUT Experts – Presentation to PolSV Investors!

I am proud to announce that the Athermalized technology has been recognized by a panel of experts from the Warsaw University of Technology and selected for presentation to PolSV in

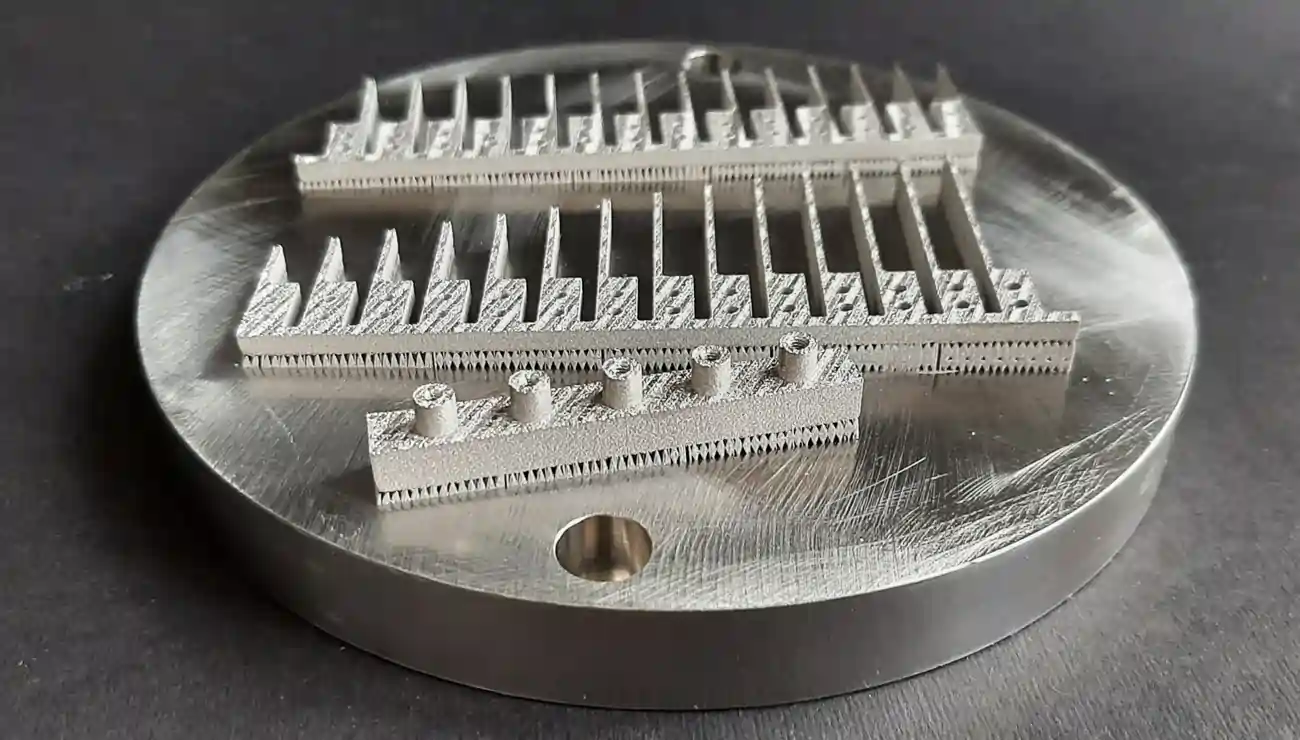

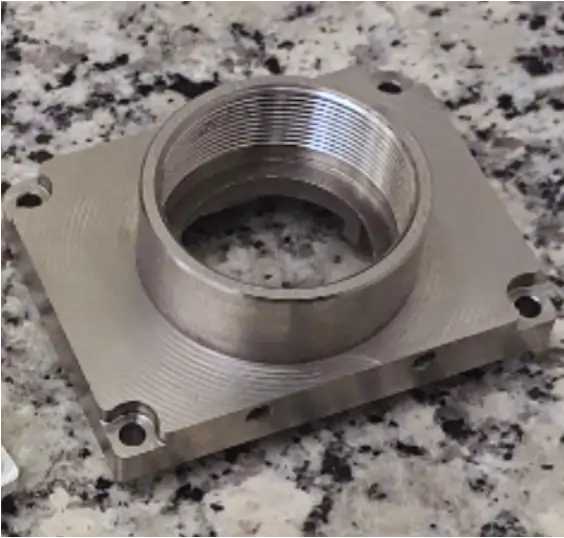

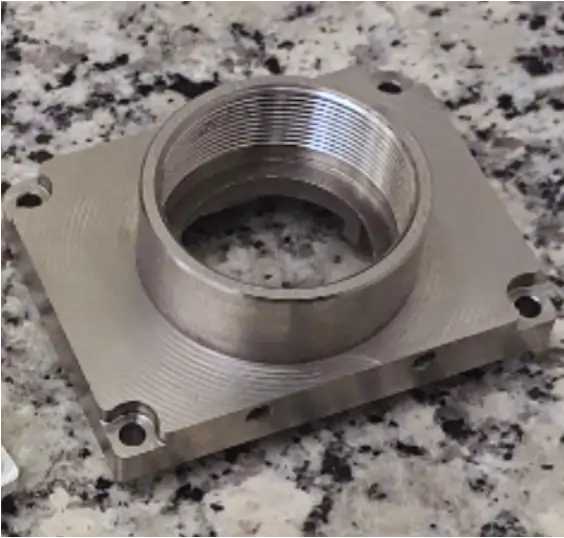

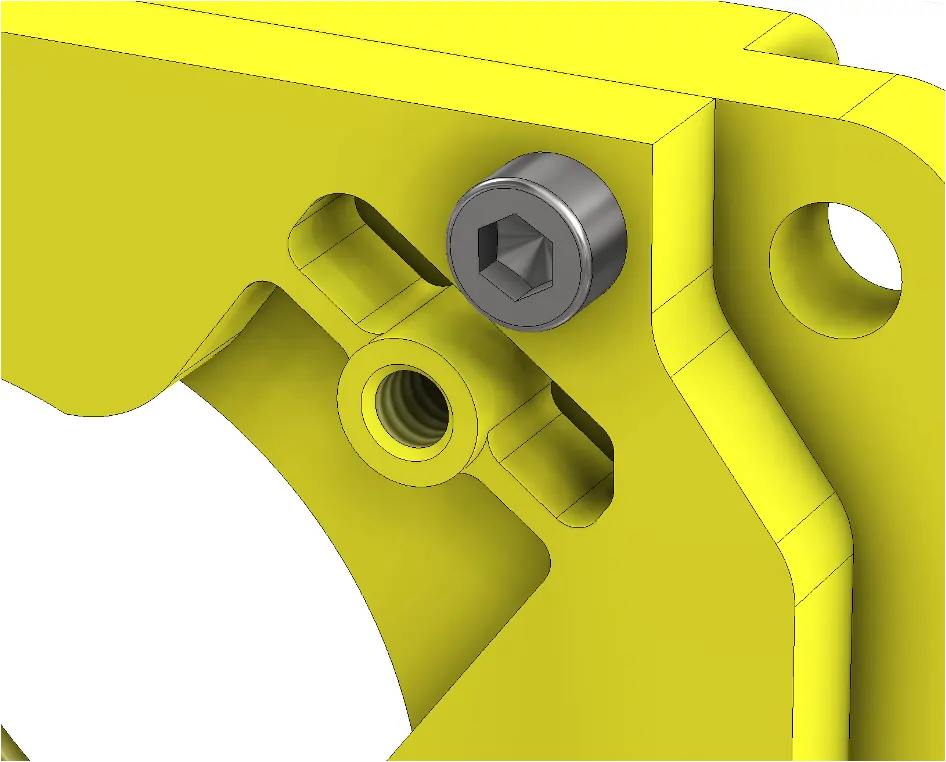

Second 3D print

We decided to expand our knowledge of metal 3D printing technology and commissioned prints of the same test specimens from Spes3D. This time we also evaluated the repeatability of

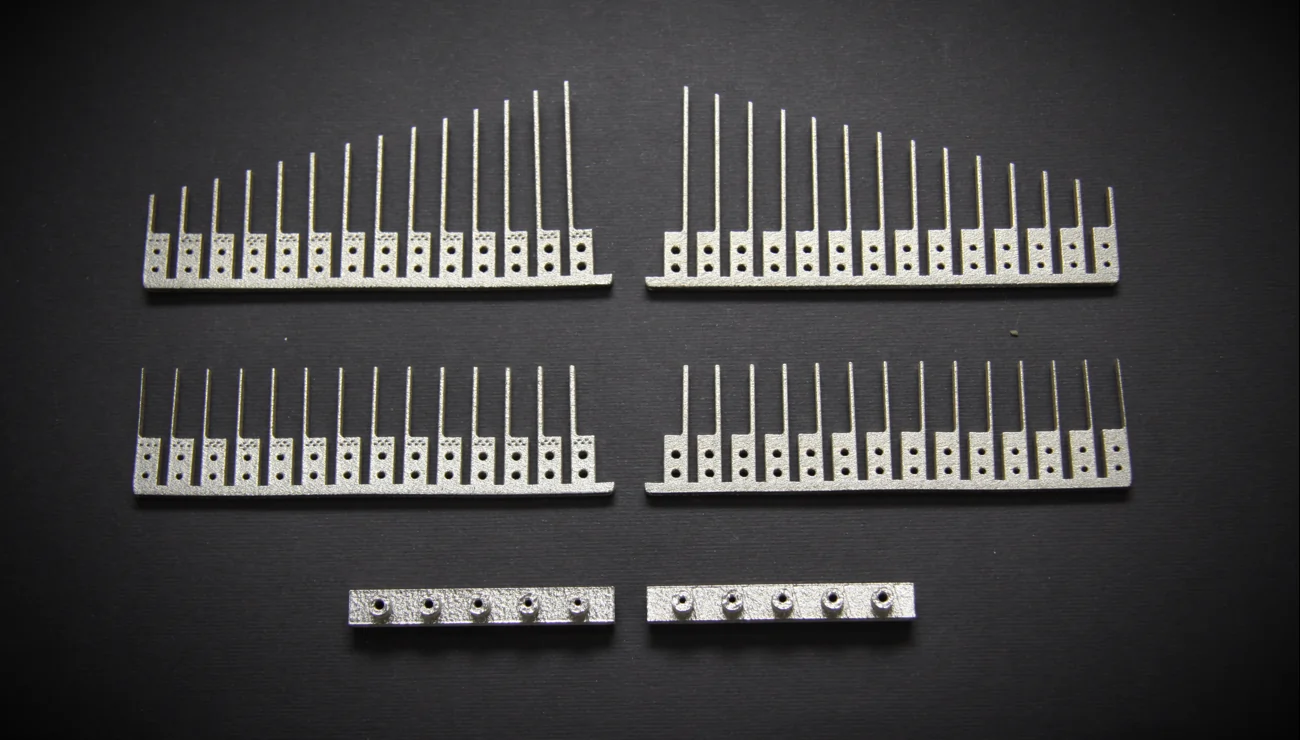

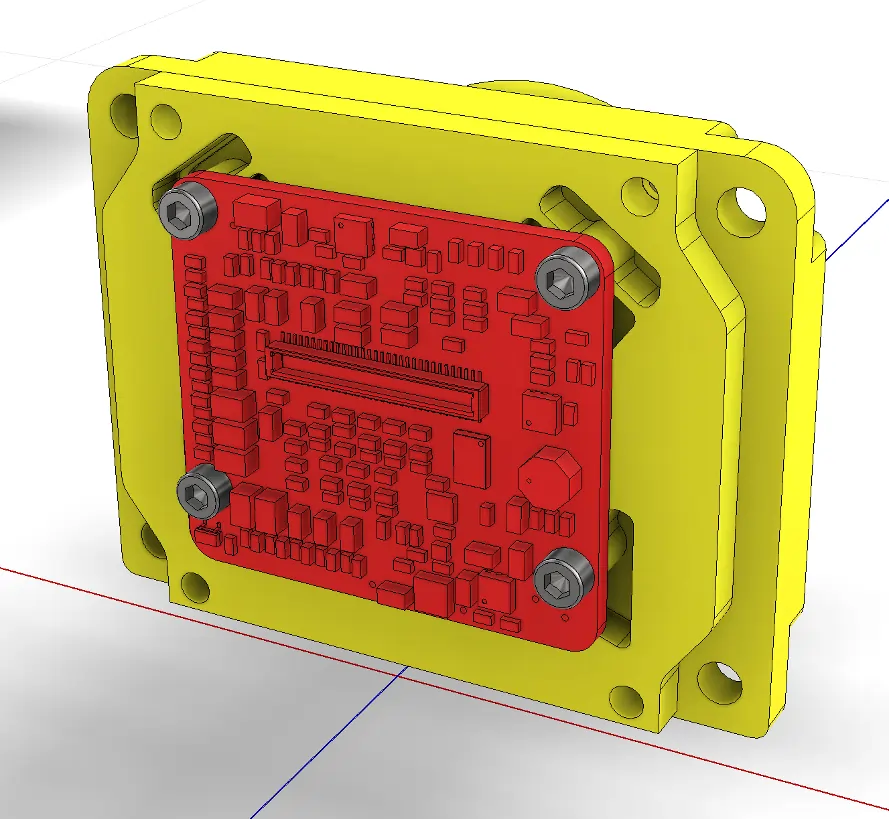

First 3D print

One of the project’s goals is to create a suspension that maintains thermal degrees of freedom for the PCB with a CMOS sensor. The suspension will be manufactured using metal

What is temperature-induced image drift in cameras?

In the field of optical engineering, cameras are essential tools used in areas such as machine vision, autonomous vehicles, medical imaging, and security systems. Their precision d

We have obtained funding for development

Success! We have received funding for the development of Athermalized technology! As part of the FENG Proof of Concept competition organized by the Foundation for Polish Science, w